Does your business have any of these problems?

- Regular corrective maintenance

- Delayed response time for technical support

- High rework rate

- Lack of data for decision making

- Lack of maintenance management

- Low machining performance

- Constant alarms and failures

If your tooling efficiency is important to you, we can help.

We provide technical services focused on training, as well as optimizing and maintaining CNC machines.

With our Marco Zero process, we map the general conditions of the equipment and then create an Action Plan listing what must be corrected to transform machine downtime into results.

CHECK OUT OUR PORTFOLIOCNC maintenance service

With over 15 years of experience in CNC maintenance, we feel confident in supplying premium technical support to our customers and businesses partners.

Less downtime, more productivity and profit

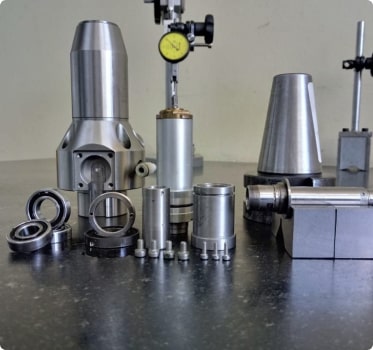

Equipped with Vibration Tester, Ballbar test, Thermographic Camera, and precision instruments,

we conduct pre and post correction diagnoses to generate indicators of the achieved results.

Grounded on Corrective, Preventive and Predictive maintenance techniques,

we have refined the concepts for what we call Detective Maintenance.

What do our customers say about CNCMOVE?

Experience with large customers

We are pleased of supporting the maintenance of CNC machines

for big names in the market

Contact us

If your tooling efficiency is important to you, contact us.

We will keep your CNC equipment available and accurate.

Copyright © 2022 CNCMove. All rights reserved.

Website developed by B3 Marketing